Increasing the Life of the Switches

MOSFETs are commonly used in BLDC motor control applications to switch high currents and control the speed and direction of the motor. The lifespan of MOSFETs can bensignificantly affected by the stress placed on them, such as high temperatures and current levels, and the frequency at which they switch on and off. We will discuss some ways to optimize the switching frequency of MOSFETs to increase their lifespan.

The Switching Frequency of MOSFETs The switching frequency of MOSFETs refers to the rate at which they switch on and off. This frequency is measured in Hertz (Hz) and is determined by the design of the motor control circuit. The optimal switching frequency depends on the specific motor and application, as well as the MOSFET’s characteristics. Factors to Consider for Optimizing Switching Frequency.

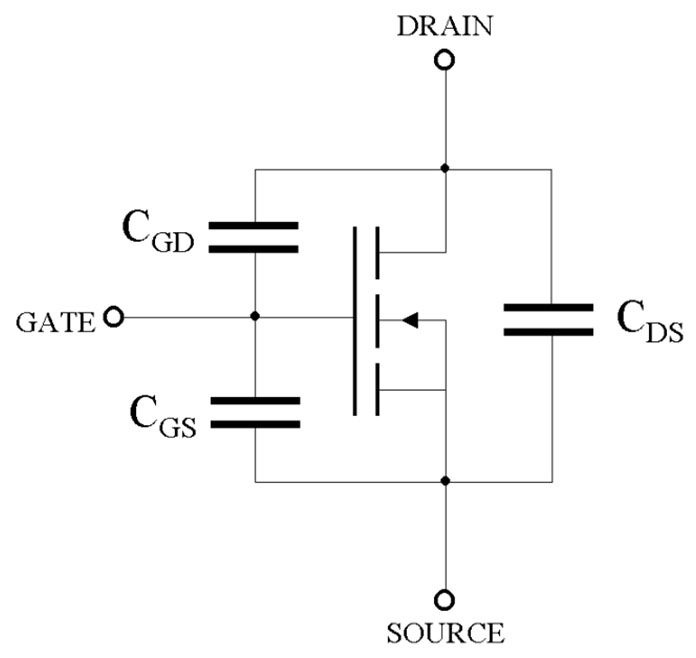

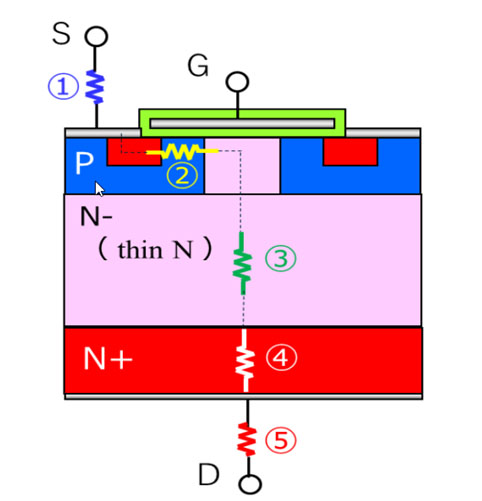

MOSFET Capacitance

The MOSFET has inherent capacitance between the gate and source terminals, limiting the MOSFET’s ability to switch at highm frequencies. To allow for higher switching frequencies, it is essential to choose MOSFETs with low gate-source capacitance CGS.

Power Dissipation

Switching at high frequencies can cause significant power dissipation in the MOSFET, leading to overheating and failure. Therefore, it is essential to design the circuit with proper heat management and choose MOSFETs with low on-resistance (RDS(on)) to minimize power dissipation.

Current & Voltage Ratings

The MOSFET’s current and voltage ratings must be sufficient for the specific motor and application. The current rating must be able to handle the maximum current that the motor will draw, and the voltage rating must be able to handle the maximum voltage that the MOSFET will experience.

Switching Losses

Switching losses occur when the MOSFET switches ON & OFF, and energy is dissipated as heat. The switching losses increase with the switching frequency and can cause the MOSFET to overheat and fail. Therefore, it is essential to choose MOSFETs with low switching losses and optimize the circuit design to minimize switching losses.

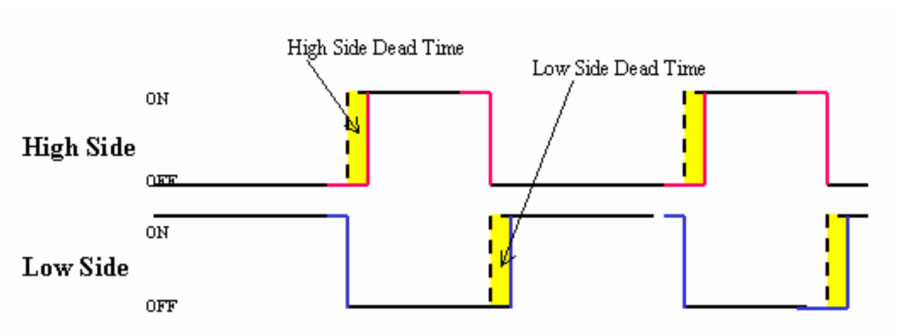

Dead Time

Dead time is the time between turning off one MOSFET and turning on the other MOSFET in a half-bridge circuit. Dead time is necessary to prevent shoot-through current, which can damage the MOSFETs. It is essential to design the dead time properly to optimize the switching frequency and prevent damage to the MOSFETs. Formulas for Optimizing Switching Frequency Here are some formulas to consider when optimizing the switching frequency:

MOSFET Gate Charge:

Qg= Vgs x Cgs,

where Vgs is the gate-source voltage,

and Cgs is the gate-source capacitance.

Turn-Off Time:

toff = Rg x Coss,

where Rg is the gate resistance

and Coss is the output capacitance.

By optimizing the switching frequency using the above factors and formulas, the lifespan of MOSFETs can be significantly increased. This can be beneficial for any electronic device that uses MOSFETs, including power supplies, LED lighting, and motor control applications.